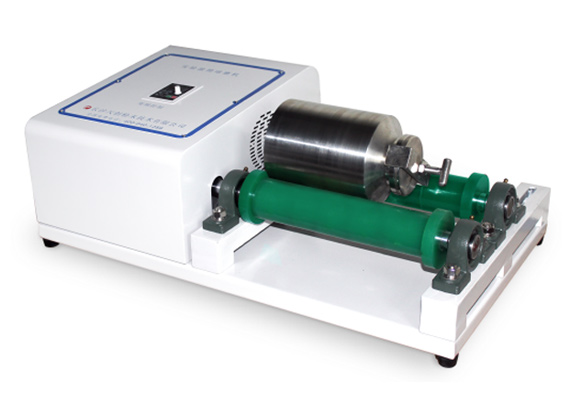

Roll ball mill is equipped with several grinding balls inside the drum. When the motor rotates, it drives the drum to rotate. During the vertical circular movement of the grinding balls and materials inside the drum, they collide with each other to grind the materials. Due to the uniform rotation of the cylinder and the grinding balls inside the cylinder in the same direction as the material, the collision energy and probability between the balls and the materials are greatly reduced, resulting in a decrease in the grinding effect and efficiency; When the rotational speed n ≥ n0, due to the centrifugal force, both the grinding balls and the materials adhere to the inner wall of the drum and rotate, losing the collision between them, and also unable to play a grinding role. Therefore, it is not easy to use a roller ball mill to achieve a grinding effect of very fine particle size and a mixing effect with uniform particle size.

Planetary ball mill is quite different from the roll ball mill in that the materials and balls in the planetary ball mill undergo high-energy motion in a two-dimensional rotating space. Two or four ball milling tanks are symmetrically installed on a rotary table. When the main disc of the rotary table rotates, the ball milling tanks rotate around their respective central axes, and the grinding balls inside the tanks grind and mix the samples in high-speed motion. At a certain moment, the strong centrifugal force generated by the large rotary table separates the ground materials from the inner wall of the tank, and under high-speed conditions of rotation, the balls and materials fly from one side of the tank to the other, colliding with each other, resulting in smaller and finer particles of the ground materials. Due to the simultaneous action of the centrifugal forces of revolution and rotation on the grinding balls and materials, and the direction of the combined force constantly changing, the motion trajectory of the grinding balls and material in the tank is disorderly. This allows the grinding balls and materials to obtain sufficient collision energy by increasing the rotational speed, and achieve a high efficient grinding effect.

China Tennan planetary ball mill utilizes the principle of planetary revolution and rotation, and the grinding balls and materials move at high speed inside the grinding jars, generating high-energy friction and impact force to achieve sample crushing, which can quickly grind the sample of material into particle size of below 1 μm. It is suitable for grinding materials from hard to soft and brittle samples in the laboratories and samples in suspension. It is a good choice and an ideal selection for ultra-fine powder grinding, sample processing in the pharmaceutical industry, sample preparation of new materials, and mechanical alloy and mechanical activation of materials. It is mainly used in laboratory laser spectral analysis, chemistry, pharmacy, biology, glass, ceramics, building materials, precision grinding of coal raw materials, pretreatment of laboratory samples in the food industry and research fields of material technology, geology, mineralogy and nuclear industry.